-

Application Industry: Rail Transit

Application Industry: Rail Transit -

Application Industry: Sanitation Machinery

Application Industry: Sanitation Machinery -

Application industry: coal mine machinery

Application industry: coal mine machinery -

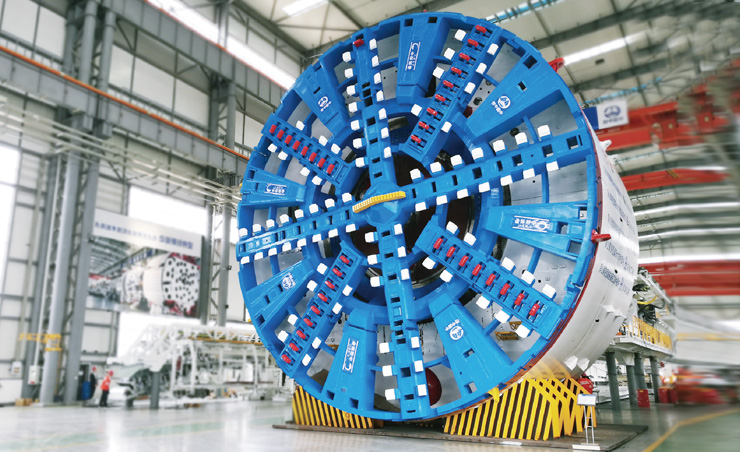

Application Industry: Tunnel Engineering

Application Industry: Tunnel Engineering

Equipment On-site Maintenance

Equipment On-site Maintenance  Spare Parts Supply Management Service

Spare Parts Supply Management Service  Maintenance And Remanufacturing

Maintenance And Remanufacturing  Full Life Cycle Specialization Package Service

Full Life Cycle Specialization Package Service  Easy-to Equipment

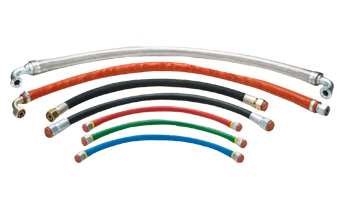

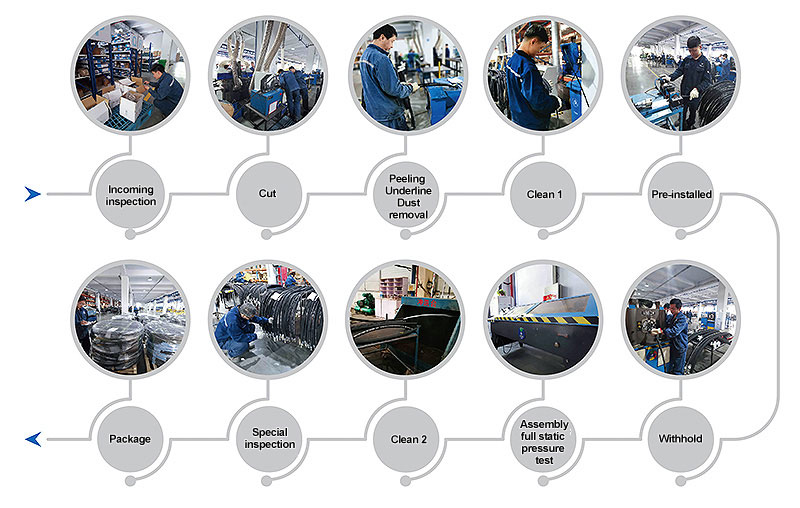

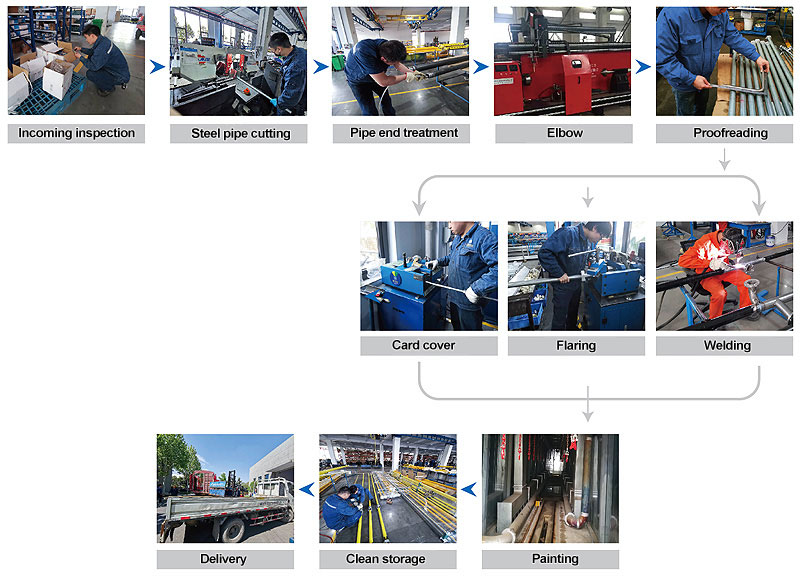

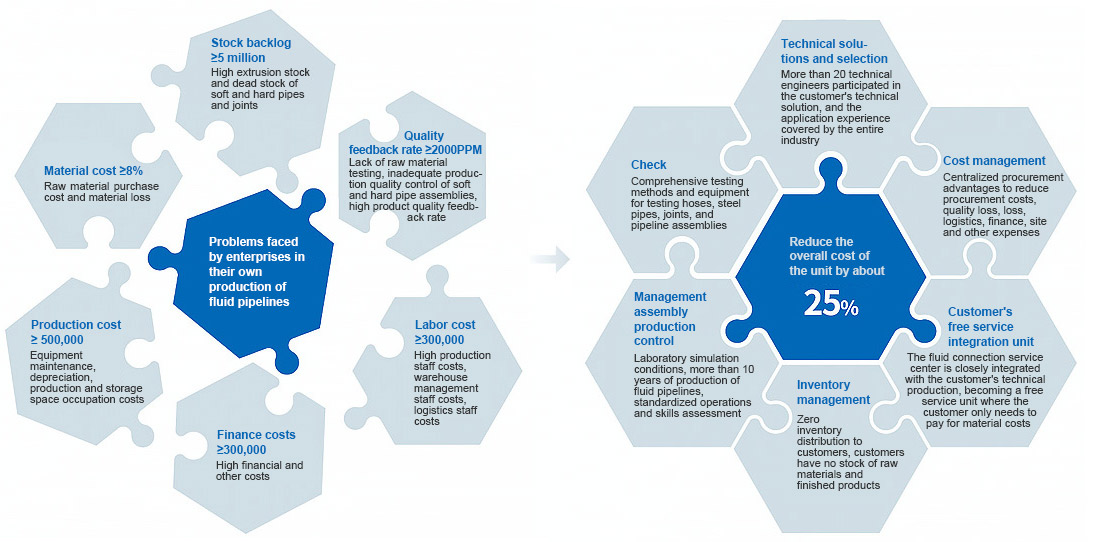

Easy-to Equipment  Fluid Service Center

Fluid Service Center  Fluid Service Center

Fluid Service Center

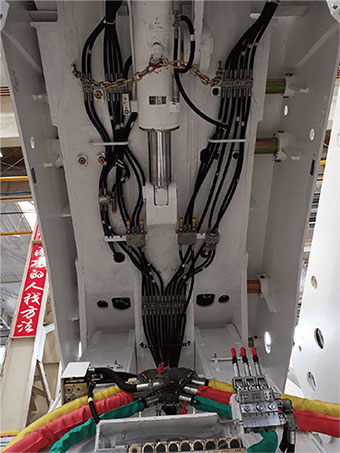

Transformation of the former

Transformation of the former

After transformation

After transformation